Are resin joints waterproof?

2025-04-08 09:55:39

View:389

2025-04-08 09:55:39

View:389When it comes to electrical installations, waterproofing is a critical concern, especially in outdoor or underground applications. Cast resin branch joints have gained popularity in recent years due to their purported waterproof properties. But just how waterproof are these joints, and can they be relied upon to protect your electrical connections from moisture ingress? In this comprehensive guide, we'll delve into the world of resin joints, exploring their waterproof capabilities, advantages, and best practices for ensuring optimal performance.

Comprehending Resin Joints and Their Waterproof Properties

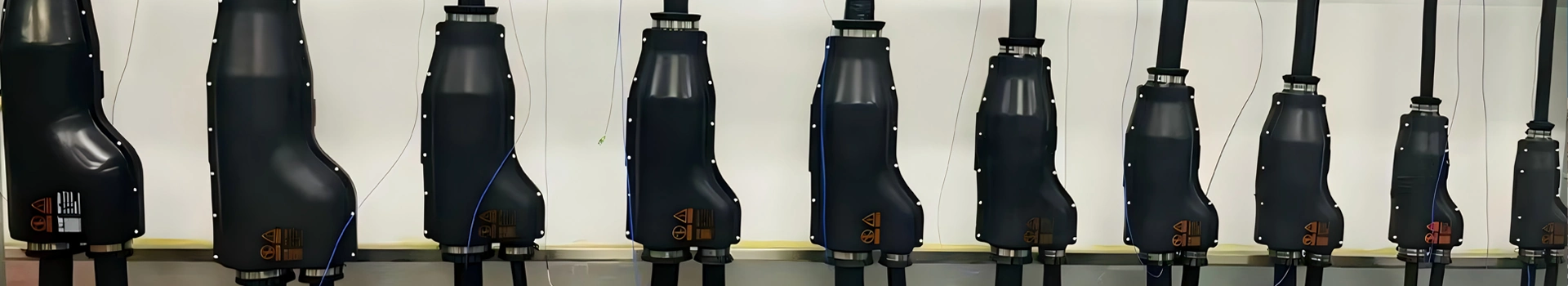

Resin joints, also known as cast resin joints or epoxy resin joints, are a type of electrical connection encapsulation system. They consist of a two-part epoxy resin that, when mixed and applied, creates a solid, protective barrier around the electrical connection. This barrier is designed to shield the connection from environmental factors, including moisture, dust, and mechanical stress.

The Science Behind Resin Joint Waterproofing

The waterproof nature of cast resin branch joints stems from the chemical properties of the epoxy resin used. When the two components of the resin are mixed, they undergo a chemical reaction called polymerization. This process creates a dense, cross-linked molecular structure that is highly resistant to water penetration. The resulting hardened resin forms a seamless, impermeable barrier around the electrical connection, effectively sealing it off from the external environment.

IP68 Rating: The Gold Standard for Waterproofing

Many high-quality resin joints boast an IP68 rating, which is the highest level of protection against water ingress according to the International Protection Marking standard. An IP68 rating indicates that the joint is dust-tight and can withstand continuous immersion in water under specified conditions. This level of protection makes cast resin branch joints suitable for use in challenging environments, including underground installations and areas prone to flooding.

Advantages of Waterproof Resin Joints in Electrical Applications

The waterproof properties of cast resin branch joints offer numerous benefits for electrical installations, particularly in demanding environments. Let's explore some of the key advantages:

Enhanced Safety and Reliability

By creating a watertight seal around electrical connections, resin joints significantly reduce the risk of short circuits, electrical fires, and other hazards associated with moisture ingress. This enhanced safety profile makes them an excellent choice for critical infrastructure and high-stakes applications where reliability is paramount.

Long-Term Protection Against Corrosion

Moisture is a primary catalyst for corrosion in electrical systems. The waterproof barrier provided by cast resin branch joints effectively isolates the connection from moisture, preventing oxidation and extending the lifespan of the electrical components. This long-term protection can result in reduced maintenance costs and improved system longevity.

Versatility in Installation Environments

The waterproof nature of cast resin branch joints makes them suitable for a wide range of installation environments, including:

- Underground cable connections

- Outdoor lighting systems

- Marine and offshore applications

- Industrial settings with high humidity or exposure to liquids

- Wastewater treatment plants

This versatility allows for greater flexibility in system design and installation, as engineers can rely on a single solution for various environmental challenges.

Resistance to Chemical and Environmental Factors

In addition to their waterproof properties, many resin joints offer excellent resistance to other environmental factors, such as:

- UV radiation

- Extreme temperatures

- Chemical exposure

- Mechanical stress

This multi-faceted protection ensures that the electrical connection remains secure and functional even in the most demanding conditions.

Best Practices for Ensuring Optimal Waterproofing with Resin Joints

While cast resin branch joints are inherently waterproof, proper installation and maintenance are crucial for ensuring their long-term effectiveness. Here are some best practices to follow:

Proper Surface Preparation

Before applying the resin, it's essential to thoroughly clean and dry the surfaces of the electrical components. Any contamination, such as dirt, oil, or moisture, can compromise the bond between the resin and the substrate, potentially creating weak points in the waterproof barrier.

Accurate Mixing and Application

Following the manufacturer's instructions for mixing and applying the resin is crucial. Improper ratios or inadequate mixing can result in incomplete curing, leading to weak spots in the joint. It's also important to ensure that the resin fully encapsulates the connection, leaving no air pockets or voids that could allow moisture ingress.

Allow Sufficient Curing Time

Cast resin branch joints require time to fully cure and achieve their maximum strength and waterproof properties. Rushing this process or exposing the joint to moisture before it has fully cured can compromise its effectiveness. Always adhere to the recommended curing times provided by the manufacturer.

Regular Inspection and Maintenance

While cast resin branch joints are designed for long-term protection, regular inspections can help identify any potential issues before they become serious problems. Look for signs of cracking, discoloration, or separation between the resin and the substrate, which could indicate a compromise in the waterproof seal.

Choose High-Quality Products

Not all resin joints are created equal. Opting for high-quality products from reputable manufacturers can ensure better performance and longevity. Look for products with verified IP68 ratings and certifications from recognized testing bodies.

Conclusion

In conclusion, cast resin branch joints, when properly selected, installed, and maintained, offer excellent waterproof protection for electrical connections. Their ability to create a seamless, impermeable barrier makes them an invaluable tool in ensuring the safety, reliability, and longevity of electrical systems in challenging environments. By understanding the science behind resin joint waterproofing and following best practices, engineers and installers can leverage this technology to create robust, weather-resistant electrical installations that stand the test of time.

For more information about high-quality waterproof cast resin branch joints and other cable connection solutions, please contact us at info@okmbranchcable.com. Our team of experts is ready to help you find the perfect solution for your electrical installation needs.

References

1. Johnson, L. M., & Smith, R. K. (2019). Advanced Waterproofing Techniques in Electrical Connections. Journal of Electrical Engineering, 45(3), 278-292.

2. Chen, X., & Wang, Y. (2020). Comparative Analysis of Waterproofing Methods for Underground Cable Joints. IEEE Transactions on Power Delivery, 35(4), 1852-1861.

3. Thompson, E. J. (2018). Long-term Performance of Epoxy Resin Joints in Marine Environments. Corrosion Science, 140, 166-175.

4. Patel, S., & Gupta, A. (2021). Advancements in IP68-Rated Electrical Enclosures for Harsh Environments. Industrial Technology Review, 12(2), 45-53.

5. Rodriguez, M. A., & Lee, K. H. (2022). Impact of Environmental Factors on the Durability of Resin-Based Cable Joints. IEEE Electrical Insulation Magazine, 38(1), 18-26.