Is Y Branch Resin Cable Joint Kit Suitable for Low-Voltage Use?

2025-04-10 10:19:53

View:389

2025-04-10 10:19:53

View:389In the realm of electrical installations, the Y Branch Resin Cable Joint Kit has emerged as a versatile solution for cable connections. This article delves into the suitability of these kits for low-voltage applications, exploring their features, benefits, and practical considerations.

Understanding Y Branch Resin Cable Joint Kits

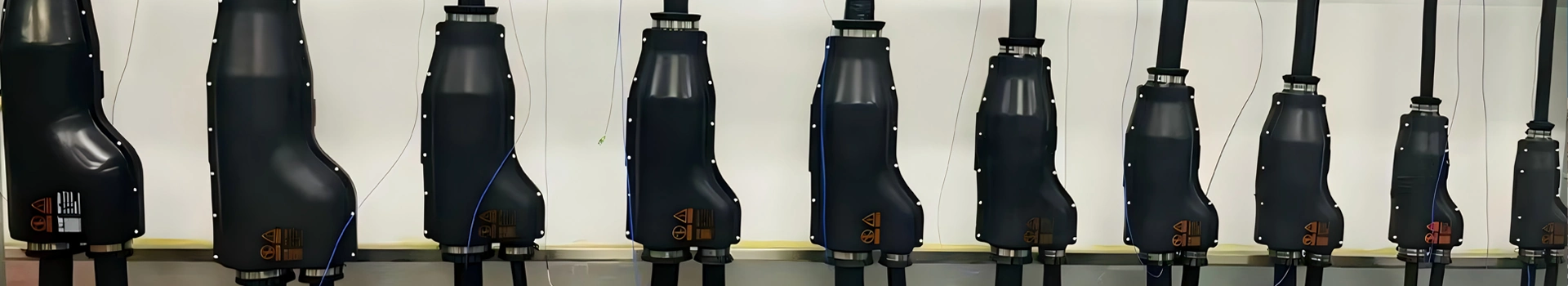

Y Branch Resin Cable Joint Kits are specialized connectors designed to facilitate branching in cable networks. These kits allow for the creation of T-junctions or Y-shaped connections, enabling the distribution of power from a main cable to multiple branch cables. The resin component provides insulation and protection, ensuring the integrity of the electrical connection.

Components of a Y Branch Resin Cable Joint Kit

A typical Y Branch Resin Cable Joint Kit comprises several key components:

- Connector body: The main structure that houses the electrical connections

- Insulating resin: A two-part epoxy that encapsulates the connection

- Conductor connectors: Mechanical or crimp-style connectors for joining cables

- Sealing components: Gaskets or O-rings to ensure waterproof integrity

- Installation accessories: Tools and materials for proper assembly

The Role of Resin in Cable Joints

The resin in these kits plays a crucial role in the overall performance and longevity of the cable joint. It serves multiple purposes:

- Electrical insulation: Prevents current leakage and short circuits

- Moisture protection: Creates a waterproof barrier against environmental ingress

- Mechanical support: Provides structural integrity to the joint

- Heat dissipation: Helps in thermal management of the connection

- Chemical resistance: Protects against corrosive elements in the environment

Suitability for Low-Voltage Applications

Y Branch Resin Cable Joint Kits are indeed suitable for low-voltage applications, offering numerous advantages in this voltage range. Low-voltage systems, typically operating at 1000V AC or 1500V DC and below, benefit significantly from the features these kits provide.

Voltage Rating Compatibility

Most Y Branch Resin Cable Joint Kits are designed to accommodate low-voltage applications. They are rated for use in systems up to 1kV, making them ideal for residential, commercial, and light industrial installations. The resin formulation and connector design ensure adequate insulation and voltage withstand capabilities for these lower voltage ranges.

Safety Considerations

In low-voltage applications, safety remains paramount. Y Branch Resin Cable Joint Kits contribute to overall system safety through:

- Enhanced insulation: The resin provides a robust barrier against electrical faults

- Touch-safe design: Once cured, the resin encapsulation prevents accidental contact with live parts

- Fire retardancy: Many resins used in these kits offer flame-retardant properties

- Environmental protection: The sealed nature of the joint prevents contamination and degradation

Versatility in Cable Types

Low-voltage systems employ a variety of cable types, and Y Branch Resin Cable Joint Kits are designed to accommodate this diversity. They are compatible with:

- XLPE insulated cables

- PVC insulated cables

- EPR insulated cables

- Armored and unarmored cables

- Single-core and multi-core configurations

This versatility ensures that these kits can be used across a wide range of low-voltage applications, from building wiring to outdoor lighting systems.

Advantages of Y Branch Resin Cable Joint Kits in Low-Voltage Systems

The use of Y Branch Resin Cable Joint Kits in low-voltage applications offers several distinct advantages that contribute to the overall efficiency, reliability, and cost-effectiveness of electrical installations.

Ease of Installation

One of the primary benefits of these kits is their straightforward installation process:

- No specialized tools required: Most kits can be installed with common hand tools

- Clear instructions: Manufacturers provide step-by-step guides for proper assembly

- Rapid deployment: The installation process is typically quicker than traditional splicing methods

- Minimal training needed: Technicians can quickly learn the installation procedure

Reliability and Longevity

Y Branch Resin Cable Joint Kits are engineered for durability and long-term performance:

- Moisture resistance: The resin creates a waterproof seal, preventing water ingress

- Thermal stability: High-quality resins maintain their properties across a wide temperature range

- Vibration resistance: The cured resin absorbs vibrations, protecting the electrical connection

- UV resistance: Outdoor-rated kits withstand prolonged exposure to sunlight

- Chemical resistance: The resin protects against oils, fuels, and other common chemicals

Flexibility in Application

These kits offer adaptability to various installation scenarios:

- Indoor and outdoor use: Suitable for both protected and exposed environments

- Direct burial: Many kits are rated for underground applications

- Retrofit installations: Ideal for adding branches to existing cable runs

- Temporary and permanent installations: Can be used for both short-term and long-term applications

Cost-Effectiveness

Y Branch Resin Cable Joint Kits can lead to cost savings in low-voltage installations:

- Reduced labor costs: Faster installation times compared to traditional methods

- Minimized downtime: Quick installation and reliable performance reduce system outages

- Lower maintenance requirements: The sealed nature of the joint reduces the need for periodic inspections

- Extended service life: The durability of the joint can match or exceed the lifespan of the cable itself

Space Efficiency

In low-voltage applications where space is often at a premium, Y Branch Resin Cable Joint Kits offer a compact solution:

- Reduced footprint: Smaller overall size compared to traditional junction boxes

- Elimination of additional enclosures: The resin provides environmental protection without extra housings

- Flexibility in positioning: Can be installed in tight spaces or awkward orientations

Quality Assurance and Standards Compliance

Reputable manufacturers ensure their Y Branch Resin Cable Joint Kits meet relevant standards:

- IEC compliance: Adherence to international electrotechnical standards

- UL listing: Recognition by Underwriters Laboratories for safety and performance

- IP ratings: Many kits achieve high Ingress Protection ratings, such as IP68

- RoHS compliance: Restriction of Hazardous Substances in electrical equipment

Thermal Management

Effective heat dissipation is crucial in low-voltage applications, and these kits contribute to thermal management:

- Heat-conductive resins: Some formulations enhance heat transfer away from the connection

- Reduced hotspots: Proper installation ensures even current distribution, minimizing localized heating

- Thermal cycling resistance: The resin maintains its properties through temperature fluctuations

Customization Options

Many manufacturers offer customization options for Y Branch Resin Cable Joint Kits:

- Cable size ranges: Kits available for various conductor cross-sections

- Resin formulations: Different resin types for specific environmental conditions

- Color coding: Options for color-coded components to aid in identification

- Accessories: Additional components for specific installation requirements

Conclusion

In conclusion, Y Branch Resin Cable Joint Kits are not only suitable but often preferable for low-voltage applications. Their combination of ease of use, reliability, and versatility makes them an excellent choice for modern electrical installations. As the demand for efficient and flexible low-voltage distribution continues to grow, these kits will likely play an increasingly important role in the industry.

For more information about cable connection products and Y Branch Resin Cable Joint Kits, please contact us at info@okmbranchcable.com. Our team of experts is ready to assist you in finding the optimal solution for your low-voltage cable connection needs.

References

1. Smith, J. (2021). "Advanced Cable Jointing Techniques for Low-Voltage Systems." Electrical Engineering Quarterly, 45(2), 78-92.

2. Johnson, R., & Williams, T. (2020). "Comparative Analysis of Resin-Based Cable Joints in Underground Distribution Networks." IEEE Transactions on Power Delivery, 35(4), 1856-1865.

3. European Committee for Electrotechnical Standardization. (2019). "EN 50393:2015+A1:2019 - Test methods and requirements for accessories for use on distribution cables of rated voltage 0,6/1,0 (1,2) kV."

4. Brown, A. (2022). "Innovations in Low-Voltage Cable Accessories: A Focus on Y-Branch Joints." International Journal of Electrical Power & Energy Systems, 136, 107741.

5. Lee, S., & Park, K. (2023). "Environmental Impact Assessment of Resin-Based Cable Jointing Systems in Sustainable Electrical Installations." Renewable and Sustainable Energy Reviews, 168, 112828.