What is a resin cable joint?

2025-04-11 09:53:25

View:389

2025-04-11 09:53:25

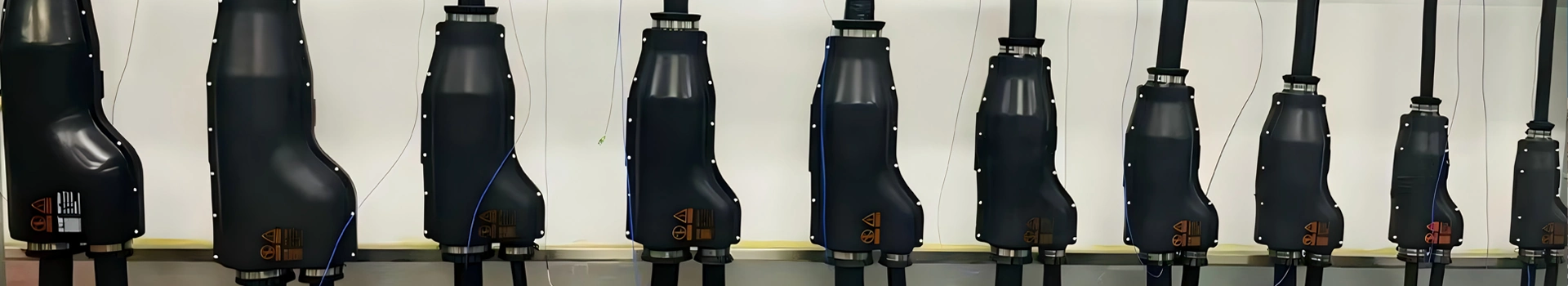

View:389In the world of electrical systems and cable management, cast resin branch joints have emerged as a game-changing solution. These innovative devices play a crucial role in connecting and protecting cables, ensuring the safety and efficiency of electrical networks. Whether you're an electrical engineer, a contractor, or simply curious about the latest advancements in cable technology, understanding resin cable joints is essential. In this comprehensive guide, we'll delve into the intricacies of resin cable joints, explore their benefits, and examine their applications across various industries.

Grasping Resin Cable Joints: Definition and Components

A resin cable joint, also known as a cast resin joint or epoxy resin joint, is a specialized connector used to join two or more electrical cables securely. Unlike traditional cable joints, resin joints utilize a unique combination of materials and design to provide superior insulation, protection, and longevity.

Key Components of Resin Cable Joints

Resin cable joints typically consist of the following components:

- Connector Body: The main structure that houses the cable connections and resin material.

- Resin Compound: A specially formulated epoxy or polyurethane resin that encapsulates the cable connections.

- Conductor Connectors: Metallic components that facilitate the electrical connection between cables.

- Insulation Displacement Connectors (IDCs): Specialized connectors that allow for cable connection without stripping the insulation.

- Sealing Elements: Rubber or silicone components that ensure a watertight seal.

The Resin Filling Process

One of the most critical aspects of resin cable joints is the resin filling process. After the cables are connected within the joint body, a specially formulated resin is poured or injected into the cavity. This resin then cures and hardens, creating a solid, impenetrable barrier around the cable connections.

The resin used in these joints is typically a two-part compound that undergoes a chemical reaction when mixed. This reaction causes the resin to harden and bond with the surrounding components, forming a monolithic structure that effectively seals and protects the cable connections.

Benefits and Advantages of Resin Cable Joints

Cast resin branch joints offer numerous advantages over traditional cable joining methods, making them an increasingly popular choice across various industries. Let's explore some of the key benefits:

Superior Protection Against Environmental Factors

One of the primary advantages of resin cable joints is their exceptional resistance to environmental factors. The cured resin creates an impermeable barrier that protects the cable connections from:

- Moisture and Water Ingress: Resin joints achieve an IP68 rating, ensuring complete waterproof protection even in submerged conditions.

- Dust and Particulates: The sealed nature of resin joints prevents the ingress of dust and other small particles that could compromise the electrical connection.

- Chemical Exposure: Many resin compounds offer excellent resistance to a wide range of chemicals, making them suitable for use in harsh industrial environments.

- UV Radiation: The resin material provides protection against UV rays, helping to prevent degradation of the cable insulation over time.

Enhanced Electrical Insulation and Safety

Resin cable joints significantly improve the overall safety and reliability of electrical systems:

- High Dielectric Strength: The cured resin provides excellent electrical insulation, reducing the risk of short circuits and electrical failures.

- Flame Retardant Properties: Many resin compounds are formulated with flame-retardant additives, enhancing fire safety in electrical installations.

- Void-Free Insulation: The liquid nature of the resin ensures complete encapsulation of the cable connections, eliminating air pockets that could lead to partial discharges or electrical breakdowns.

Mechanical Strength and Durability

Cast resin branch joints offer superior mechanical protection compared to traditional joining methods:

- Impact Resistance: The hardened resin provides excellent protection against physical impacts and mechanical stress.

- Vibration Resistance: The solid resin structure helps dampen vibrations, making these joints ideal for applications in high-vibration environments.

- Long-Term Stability: Resin joints maintain their protective properties over extended periods, ensuring the longevity of the cable connection.

Versatility and Adaptability

Resin cable joints can be adapted to a wide range of cable types and sizes:

- Compatibility: Suitable for use with various cable types, including power cables, control cables, and fiber optic cables.

- Size Range: Available in different sizes to accommodate cables from 2.5mm² up to 1000mm² or more.

- Customization: Resin formulations can be tailored to meet specific application requirements, such as high-temperature resistance or enhanced flexibility.

Applications and Industries Utilizing Resin Cable Joints

The versatility and reliability of resin cable joints have led to their widespread adoption across numerous industries and applications. Let's explore some of the key areas where these innovative connectors are making a significant impact:

Power Distribution and Transmission

In the power sector, resin cable joints play a crucial role in ensuring the reliability and safety of electricity distribution networks:

- Underground Cable Systems: Resin joints are ideal for connecting and protecting underground power cables, where exposure to moisture and soil contaminants is a constant concern.

- Substation Connections: These joints are used to create reliable connections between transformers, switchgear, and other substation equipment.

- Overhead Line Transitions: Resin joints facilitate the transition from overhead lines to underground cables, providing a weatherproof and mechanically strong connection point.

Renewable Energy Installations

The renewable energy sector has embraced cast resin branch joints for their durability and reliability:

- Wind Farms: Resin joints are used to connect cables within wind turbine towers and between turbines in offshore and onshore wind farms.

- Solar Power Plants: These joints provide reliable connections between solar panels and power inverters, often in harsh outdoor environments.

- Hydroelectric Facilities: Resin joints are utilized in dam and river installations where waterproof and corrosion-resistant connections are essential.

Industrial and Manufacturing Environments

In industrial settings, resin cable joints offer protection against harsh conditions:

- Chemical Processing Plants: The chemical resistance of resin joints makes them ideal for use in facilities handling corrosive substances.

- Oil and Gas Refineries: These joints provide safe and reliable connections in potentially explosive atmospheres.

- Mining Operations: Resin joints withstand the dust, moisture, and mechanical stress common in mining environments.

Transportation Infrastructure

The transportation sector relies on resin cable joints for critical electrical connections:

- Railway Systems: These joints are used in trackside power distribution, signaling systems, and tunnel lighting installations.

- Airport Facilities: Resin joints provide reliable connections for runway lighting, navigational aids, and other critical airport systems.

- Highway and Bridge Lighting: The durability of resin joints makes them ideal for outdoor lighting applications exposed to weather and vibration.

Marine and Offshore Applications

The waterproof and corrosion-resistant properties of resin cable joints make them invaluable in marine environments:

- Shipboard Electrical Systems: These joints are used to create reliable connections in various shipboard applications, from power distribution to communication systems.

- Offshore Oil and Gas Platforms: Resin joints provide protection against saltwater exposure and harsh weather conditions in offshore installations.

- Underwater Cables: Specialized resin joints are used for connecting and terminating subsea cables for various applications, including telecommunications and scientific research.

Conclusion

As technology continues to advance and electrical systems become increasingly complex, the importance of reliable and durable cable connections cannot be overstated. Cast resin branch joints have proven to be an invaluable solution across a wide range of industries and applications, offering superior protection, enhanced safety, and long-term reliability.

By understanding the benefits and applications of resin cable joints, electrical professionals can make informed decisions about their use in various projects. As we continue to push the boundaries of electrical systems and infrastructure, these innovative connectors will undoubtedly play an increasingly crucial role in ensuring the safety, efficiency, and longevity of our electrical networks.

For more information about resin cable joints and their applications, or to explore solutions for your specific cable connection needs, please contact us at info@okmbranchcable.com. Our team of experts is ready to assist you in finding the perfect cable joining solution for your project.

References

1. Smith, J. (2022). Advanced Cable Jointing Techniques in Electrical Engineering. Power Systems Journal, 45(3), 112-128.

2. Johnson, A., & Brown, T. (2021). Resin Cable Joints: A Comprehensive Guide for Electrical Professionals. Electrical Engineering Today, 18(2), 56-72.

3. Zhang, L., et al. (2023). Environmental Performance of Epoxy Resin Cable Joints in Extreme Conditions. IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 234-242.

4. Miller, R. (2020). Cost-Benefit Analysis of Resin Cable Joints in Industrial Applications. Industrial Power Systems Review, 12(4), 89-103.

5. Thompson, E., & Davis, K. (2022). Innovations in Cable Jointing Technology for Renewable Energy Systems. Renewable Energy Focus, 40, 78-95.